Subtotal: $0.00

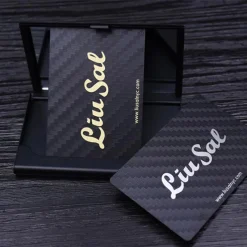

Foil Stamp Business Cards

Foil stamping, also known as foil printing, is a versatile printing technique that involves applying a metallic or pigmented foil to a surface in order to create a decorative finish. The process makes use of metal dies, combined with heat and pressure, to permanently bond a thin foil film to a paper-based substrate.

Foil Stamp Business Cards

Foil stamping, also known as foil printing, is a versatile printing technique that involves applying a metallic or pigmented foil to a surface in order to create a decorative finish. The process makes use of metal dies, combined with heat and pressure, to permanently bond a thin foil film to a paper-based substrate.

Foil Stamp Business Cards

Foil stamping, also known as foil printing, is a versatile printing technique that involves applying a metallic or pigmented foil to a surface in order to create a decorative finish. The process makes use of metal dies, combined with heat and pressure, to permanently bond a thin foil film to a paper-based substrate.

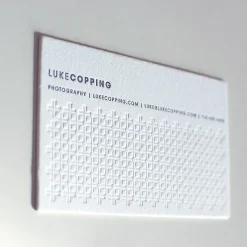

Embossed Business Cards

Debossing is when an image is imprinted into your print piece, creating a depressed effect. Just like embossing, you can choose to leave the debossed area untouched or fill it in with ink or foil stamping.Unlike embossing, debossing doesn’t interfere with the back of your print piece, giving you both sides to work with. It can be used on its own, or in conjunction with embossing.

Embossed Business Cards

The first part of the embossing process is the creation of the die, which is made up of two metal plates that will sandwich the paper. Next, the printer places the stock between the front and back of the die. If you’re having an image embossed, the female die will go on top of the stock and male die will go on the bottom as the counterdie.

Spot UV Business Cards

Spot UV refers to the application of a clear polymer coating to a specific area (or areas) of a printed piece to highlight it, rather than coating the entire surface of a printed item.

Edge Painted Business Cards

Edge painting on its surface sounds pretty simple – it’s a process by which color is applied to the edges of cards, invitations, even books or journals. Edge painting can be done in any color, including metallics and foils , and is usually mixed by hand to be matched to a specific Pantone color.

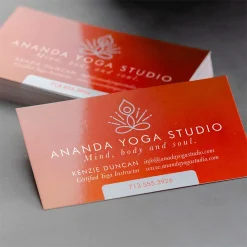

Standard Business Cards

Glossy laminate films add a shiny, glass-like appearance to printed materials. A gloss laminate also greatly enhances the color and vibrancy of the underlying ink.

Foil Stamp Business Cards

Foil stamping, also known as foil printing, is a versatile printing technique that involves applying a metallic or pigmented foil to a surface in order to create a decorative finish. The process makes use of metal dies, combined with heat and pressure, to permanently bond a thin foil film to a paper-based substrate.

Foil Stamp Business Cards

Foil stamping, also known as foil printing, is a versatile printing technique that involves applying a metallic or pigmented foil to a surface in order to create a decorative finish. The process makes use of metal dies, combined with heat and pressure, to permanently bond a thin foil film to a paper-based substrate.

Laser Cut Business Cards

Laser Cutting is a non-contact process which utilizes a laser to cut materials, resulting in high quality, dimensionally accurate cuts. The process works by directing the laser beam through a nozzle to the workpiece. A combination of heat and pressure creates the cutting action.

Blue foil stamp business cards

Blue foil stamp business cards